Love Me Tender

Welcome back for chapter two of your continuing twelve-part series in advanced Zeelander ownership. In the end you’ll be awarded your well-deserved Masters in Zeelander Yachts degree. This week we try to answer that age-old question of yachting, reportedly first asked by H.M.S. Bounty’s Captain Bligh himself: Where is the best place to store my […]

Time and Tide…

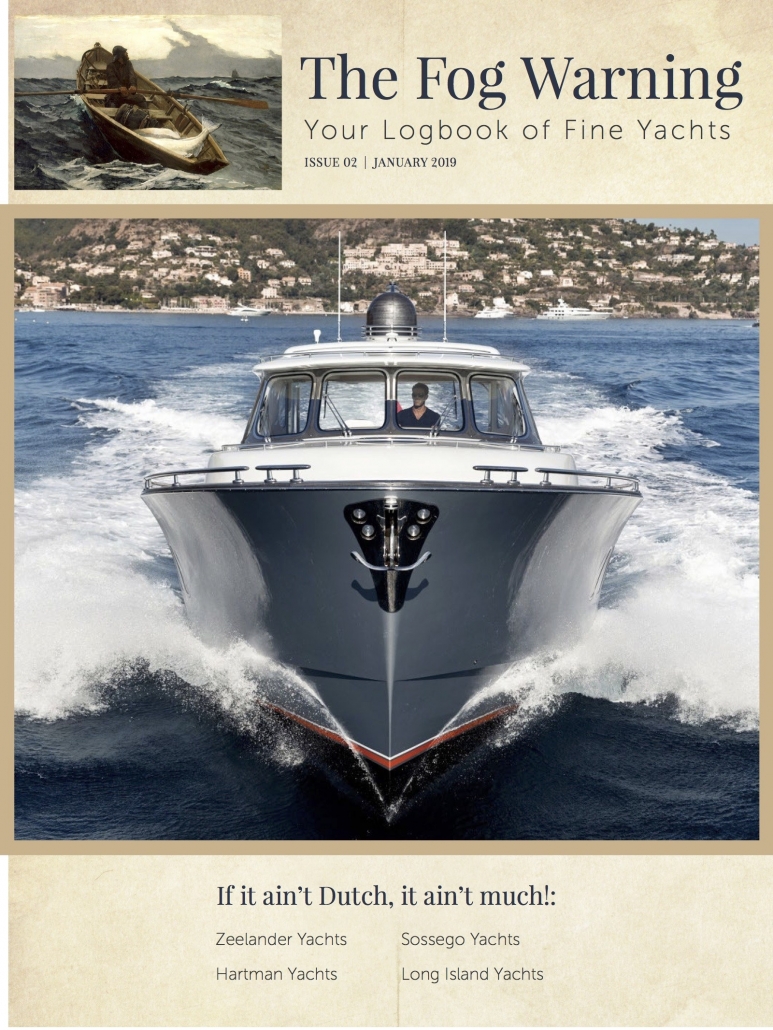

I. The Magazine! At least one of your holiday wishes has been granted! The Winter issue of The Fog Warning Digital Magazine has just been published on the Apple and Google App stores: The winter issue contains 178 pages of cool articles and in-depth listings of featured yachts. You can subscribe to this free and […]

Solutions

I. A Christening I was shocked to learn that long after his heroic WWI exploits in the Middle East, Lawrence of Arabia swapped his camels for boats and became a successful boat designer. By all accounts, Sir Lawrence was pretty good at it. Here is a wonderful video of the 1938 christening of his record-breaking hydroplane, Empire Day: Now I’m […]

Gemstone Quality

I. Gemstone Quality A client recently asked me if The Fog Warning had a specific theme. I quickly said: “Sure! On any given day I write about whatever yachts I like.” But thinking about it later, that seemed just a little shallow. With this new year approaching us, and excited by some improvements you may have […]